Inventomatic Seals

Precision systems in motion…

Precision systems in motion…

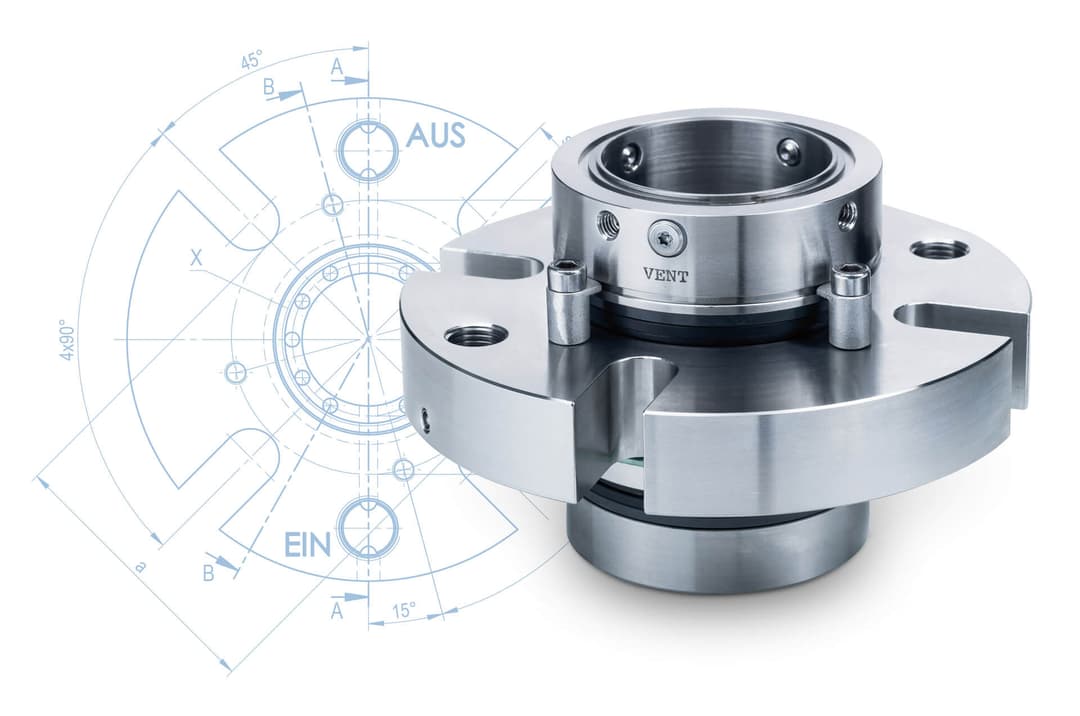

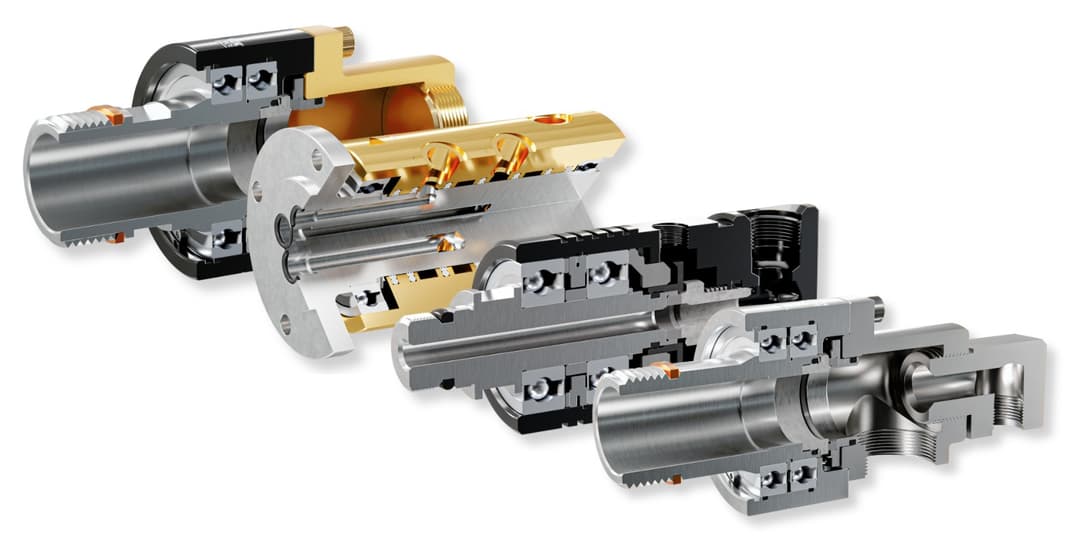

At Inventomatic Seals India, we provide comprehensive refurbishment and reconditioning services for all types of mechanical seals, rotary joints, and related sealing components. Instead of investing in costly replacements, our in-house ISO-certified facility restores worn or damaged seals and joints to their original OEM performance standards—backed by precision engineering and performance testing. Our refurbishment program is designed to reduce your maintenance costs, extend service life, and minimize downtime across various industries, from chemical processing to power generation.

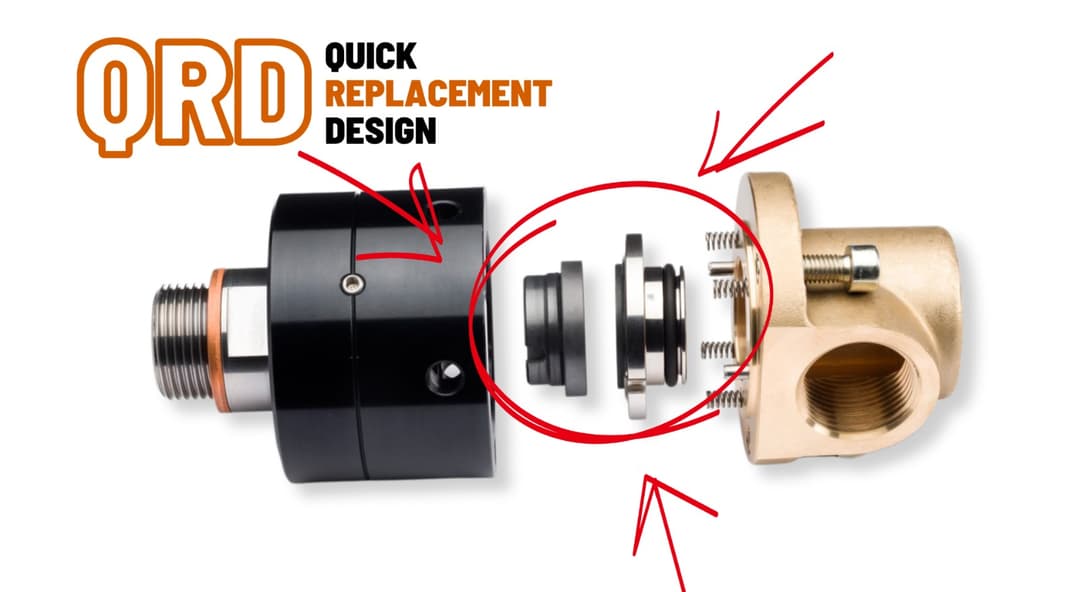

Cost-Effective Solutions • Custom Pricing: You pay only for the services actually required—no flat rates or unnecessary replacements. • In-House Manufacturing: We manufacture critical components like seal faces, sleeves, and gland plates internally, giving us full control over quality and cost. • Value for Money: Save up to 40–60% compared to OEM replacement costs without compromising performance.

• ISO 9001:2015 Certified: Every refurbishment job meets international quality benchmarks. • Documented Processes: Detailed job specs, lapping records, and performance test reports are provided with every job. • Like-New Performance: Repaired seals and joints are thoroughly inspected and restored to OEM-equivalent function. Hydrostatic pressure testing available on request.

• Express Repairs: Same-day or 24-hour turnaround options available for urgent needs. • Ready Component Inventory: Stocked with common wear parts for faster service. • Skilled Team: Our trained technicians deliver consistent results with a strong focus on precision and reliability.

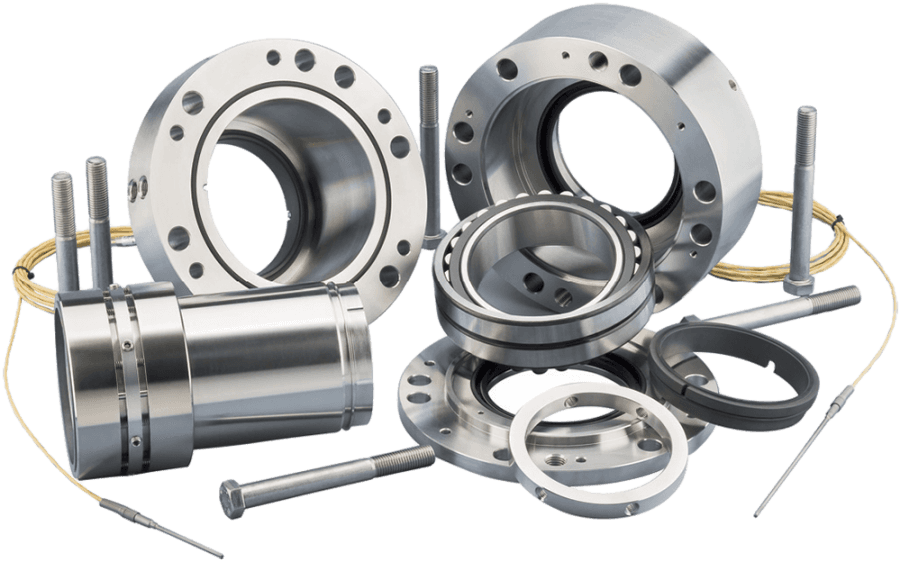

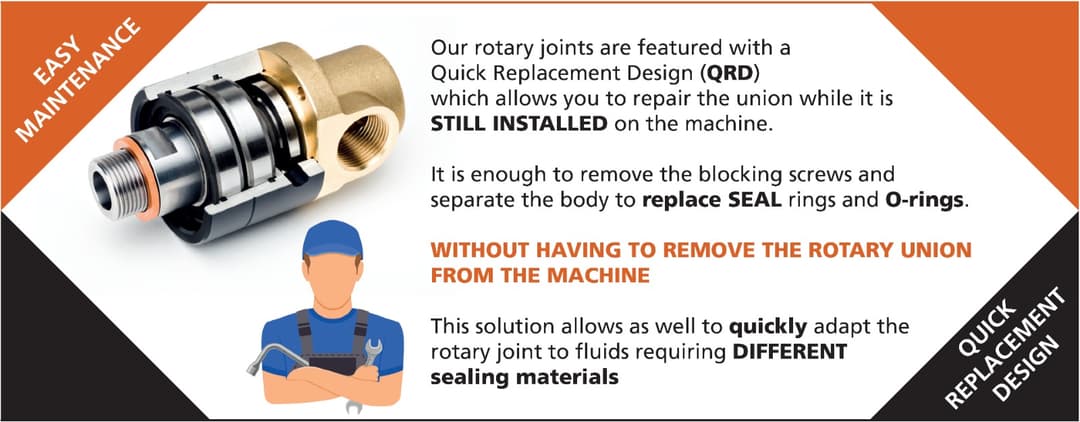

• Mechanical Seals: Single, double, balanced, unbalanced, and cartridge designs • Rotary Joints: Suitable for steam, water, thermal oil, air, and slurry applications • Seal Components: Shaft sleeves, bellows, seal faces, O-rings, gland plates • Custom Seals: OEM-equivalent or specialized assemblies for agitators, mixers, reactors, and pumps.

Save up to 60% versus new replacements, eliminate long OEM lead times, and extend equipment life by reusing existing components. Every refurbishment is fully tested, documented, and traceable, while also reducing industrial waste. With hydrostatic pressure testing, precision lapping, and certified documentation, Inventomatic restores seal and rotary joint performance without compromising quality.